BME Attachments

Frequently Asked Questions

What types of attachments does BME manufacture?

BME supplies high-performance attachments including excavator grabs, rippers, hydraulic hammers, rock breakers, and buckets—built for Australian conditions and heavy-duty applications.

Are BME attachments compatible with all major machine brands?

Yes, BME designs attachments to suit a wide range of excavators, loaders, and skid steers from brands like CAT, Komatsu, Hitachi, and Kobelco. Compatibility can be tailored with pin sizing or quick-hitch adapters.

What sets BME attachments apart in the Australian market?

Built for toughness, BME attachments are known for their wear-resistant steel, reinforced build quality, and competitive pricing. They’re ideal for civil, demolition, and quarry use.

Can BME attachments handle high-impact jobs like rock breaking?

Absolutely. BME hydraulic breakers and rippers are engineered for high-impact tasks and come in various sizes to match your carrier machine and job requirements.

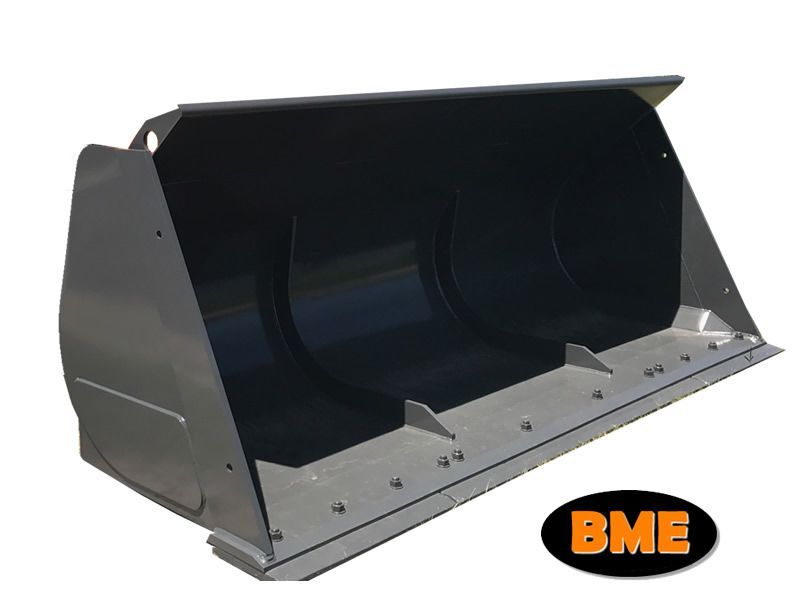

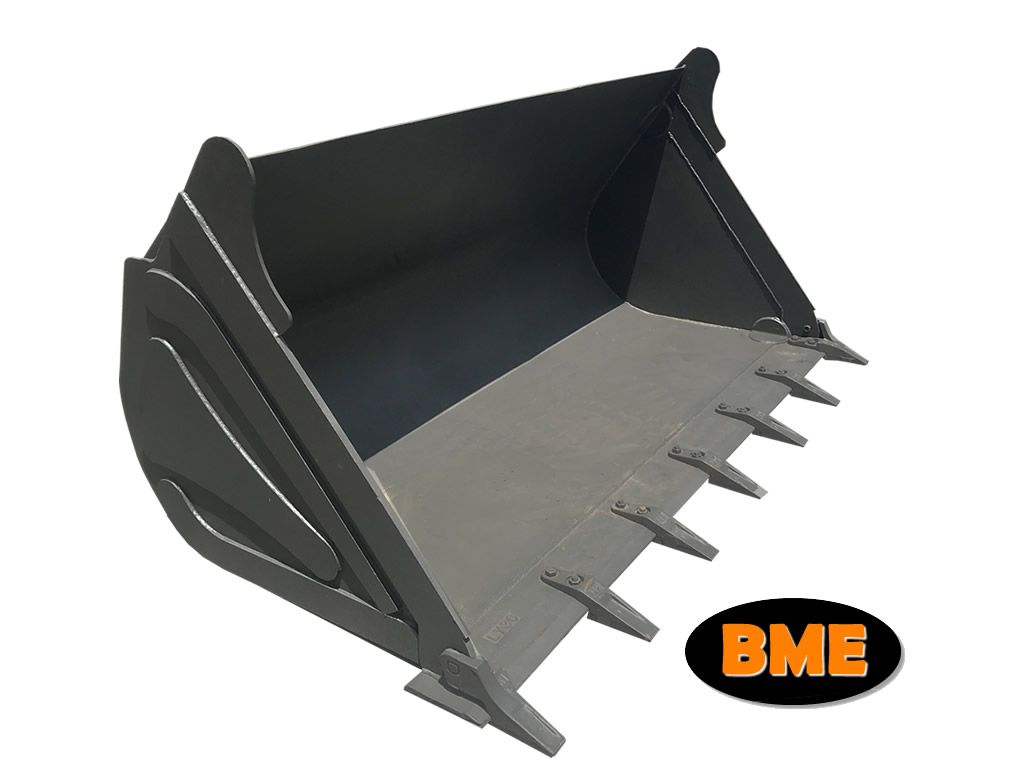

Do BME buckets come with bolt-on cutting edges or teeth?

Yes. Most BME buckets offer bolt-on options for reversible cutting edges, wear strips, or replaceable teeth—allowing flexibility across excavation, grading, or loading tasks.

Are custom attachment solutions available through BME?

Yes. If your project requires specific widths, capacities, or mounts, BME can customise or fabricate to spec—backed by local support and engineering.

What kind of warranty or after-sales support is provided?

BME attachments come with a manufacturer’s warranty and access to spare parts and servicing via Hercules Machinery Group. We also provide fitting advice and maintenance guidance.

Can BME attachments be included in a machine + attachment package deal?

Definitely. We often bundle BME attachments with new or used equipment purchases, offering value pricing, faster delivery, and better machine-attachment synergy.